| The

commercial approach: Top Ace motor works

My frend Huub Luyk knew Top Ace motor works, a

large metal workshop whose manager, mr. Benito Tiong, was

interested in Micro Hydro. Based on the firefly manual,

mr. Tiong made a price quotation and came up with a very

reasonable price: ca. US$ 150 for the charger without

switchboard. I met mr. Tiong a couple of times and

visited his workshop. Clearly, mr. Tiong was determined

to, and capable of, producing good quality chargers. He

suggested ways to produce the charger cheaper. In the

Philippines, this is not as logic as it seems, as many

business people think from the marketing side and are

primarily interested in finding new ways to sell their

products at a higher price.

|

| Now there was a problem on the demand

side: How could potential customers get in touch with Top

Ace and order a charger so that Top Ace could start

producing a small series. Top Ace would not do "turn-key

firefly projects" so other parties were needed to

advise potential users, help selecting a site, design

civil works, wire up houses, sell batteries at a

reasonable price etc. This is where ideas about good

development projects come into play. I would have loved

Top Ace to produce chargers and make a profit on it. Also

DGIS/DST/ML (the Dutch ODA dept. that funded my mission)

would like a private company to be involved and sell

commodities at realistic prices. I think that mr. John

Malamug, the manager of BSU-ANEC, was in favour of such

contacts with Top Ace. BSU-ANEC received more requests

for demonstration chargers than they could handle

themselves and likely, he will have referred such people

to Top Ace. But I doubt whether it fitted in mr. Angeles

way of working: He wanted "social projects", so

giving away chargers for free. He thought the chargers

they built themselves, were good enough so no need to

improve quality. The firefly building workshops were a

showcase success for them so I don't think that he would

like to put an end to it Also he was used to decide

himself who could be beneficiaries of his M.H. projects,

and not just sell products to customers who were willing

to pay for it. Also for PRRM it would have been a big

step to allow a private company to earn a profit from

their Micro Hydro projects. |

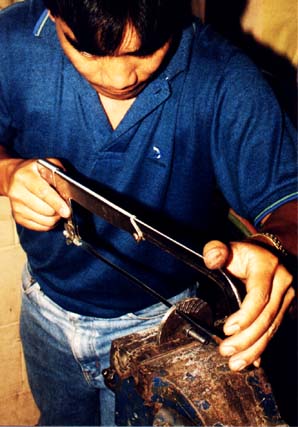

mr. Tiong (left)

looking at my jigs and jigsaw machine for cutting side

disks in series. The other people are, from left to right:

mr. Edgar Molinas, and Jackson ..., both of BSU-ANEC, and

mr. Tiong's assistant

|

| I have not been in touch

with Top Ace motor works since 1996 and I haven't heared

about any chargers being built by them.

A Philippine-wide firefly

introduction project

Besides my work for the ANEC's, I have

tried to establish contacts with other organisations in

the Philippines that could play a role in a future,

Philippine-wide firefly introduction project. At that

moment, it looked like there were possibilities for

substantial funding from DGIS/DST/ML for such a project.

But it never came off the ground:

- I did not find an organisation (or

a group of organisations) that were interested

and capable of planning such a project, applying

for funding and then implementing it.

- Dutch development aid funding was

restructured in such a way that decisions about

funding would be made at Dutch embassies instead

of in The Hague. So getting a project off the

ground was primarily a matter between a

Philippine organisation and the Dutch Embassy. As

a Dutch technical consultant, I could do little

to stimulate that process.

Is the firefly too

cheap?

When I wrote the manual, I hoped that

after some initial technology development and

introduction projects, the firefly technology would

spread by itself. This has not happened: On the whole,

the firefly plays a negligible role in providing energy

services to isolated, rural areas in the Philippines.

Meanwhile, solar energy has been introduced succesfully

in a number of developing countries and I guess the same

has happened in the Philippines. An infrastructure for

supply, installation, maintenance and repair has

developed and prices have come down. A typical Solar Home

System (SHS) consists of a solar panel, Battery Control

Unit, a battery and a few fluorescent lamps. Both the

firefly and a SHS can power about the same types of

appliances. The firefly is more flexible in terms of

energy usage as one could just have the battery recharged

more often if one would like to consume more energy. A

disadvantage of the firefly is that it requires more care

(for checking battery state of charge) and more work (for

bringing the battery to be recharged and collecting it

later).

If one looks at costs, the firefly is

much cheaper: Back in 1992, investment costs per house

for the firefly were about 1/10 of those for a SHS.

Investment costs for a SHS have come down since then and

by now, the firefly will be about 1/5 of a SHS.

Considering this price difference, one would expect that

the firefly would outcompete the SHS in those areas where

suitable sites are abundant and where people are so poor

that spending time is favourable above spending more

money. There must be quite a few such areas in the

Philippines but nowhere the firefly has realy taken off.

This makes one think about other obstacles that hampered

firefly introduction:

- Status: Clearly, a solar

panel on your roof gives another impression to

the neighbours than being seen while carrying

your battery down a slippery mountain trail.

Solar energy is high-tech, clean, shiny, silent

and luxurious while the firefly is second hand

car technology, rusty, muddy, noisy and laborious.

- Technology push: There are

large companies involved in spreading solar

energy. They have built up a supply chain that

reaches out to village level in areas where solar

energy is widespread. To finance uneconomic

demonstration projects in new areas, they have

access to development funds. The firefly will

never be promoted in such a way. In the

Philippines, the biggest car battery supplier

also produced solar batteries for Solar Home

System and was actively promoting solar energy. I

once spoke to their sales manager but he lost

interest when he learned how cheap the firefly

system is. Selling 10 Solar Home Systems and

making a decent profit margin on it, is

worthwhile. Selling one firefly charger, 10

batteries and a bunch of cables is not. They

would have to charge an excessive profit margin

on it to cover the costs of their Manilla-based

staff, customers would be angry when they would

find out and in the end, it would compete with

their solar energy activities. This leads to a

situation where the ones who might want to

introduce the firefly technology, don't have the

capacities and funds to do so while the ones who

could do it, aren't interested because they can

earn more by producing expensive goods for richer

people.

I think those reasons played a major

role in why the firefly technology never took off in the

Philippines. I realize I played a role in it myself: If I

would have been a smarter technician, I might have come

up with a good design earlier and I would have found and

solved all remaining technical issues. If I would have

been a more enthousiastic salesman, I might have gotten

this Philippine-wide introduction project off the ground.

If I would have worked harder... etc. But I doubt whether

that would have made such a difference that these two

obstacles could have been overcome. I am open to

discussion with anyone who thinks differently about this.

index page

|